Product ID:China

Product Info1:ZhongJing

Product Info2:Dry air generator equipment

Shelf time:2020-11-17

Product description:Application: The dry air generator is widely used to supply dry air for maintenance of transformer, reactor and other lar

Application:

The dry air generator is widely used to supply dry air for maintenance of transformer, reactor and other large power equipment. The dry air provided can ensure that the internal insulation of power equipment is not affected by moisture, and the maintenance personnel will not suffocate due to lack of oxygen when working inside the equipment. Compared with nitrogen, it is safe, reliable, economical and convenient. When the dry air generator is used for equipment maintenance, it is not affected by the change of external climate conditions, especially for overnight operation, it is only necessary to seal all flanges and fill 0.1 ~ 0.3MPa dry air without oil injection, and transformers and reactors will not be affected by moisture. It reduces the workload of pumping and oiling every day, shortens the maintenance period and improves the maintenance quality. In the process of oil filtering, the oil filling equipment box and oil liquid can be air dried. In rainy days and humid environment, the oil insulation can be improved and the moisture content can be reduced. After the oil depot (oil tank) is connected with the dry gas generator, it can ensure that the reserve oil in stock is in a qualified state for a long time, so as to be used at any time in the shock project. It can also be used in other warehouses, reference rooms, production places and so on.

working principle:

The atmosphere enters the gas storage tank through the air compressor, and most of the water is compressed and liquefied. The air is discharged through the drain valve and the air is dried for the first time. Then it enters the freeze dryer, where the water vapor is condensed into water, and the air is dried for the second time. Then it enters the adsorption dryer for the third drying to absorb the remaining trace water, and finally it is transported to the drying place through the high-precision air filter Gas equipment.

Features of dry air generator:

⊙ twin screw air compressor, low temperature condensation water removal technology.

⊙ small size, light weight, simple operation, energy saving, safe and reliable use.

⊙ combine the advantages of cold dryer, suction dryer and ultra fine filtration to produce high quality and low dew point dry air.

⊙ the integrated design of the machine can be equipped with PLC automatic control, automatic detection of various operating parameters, compact and reasonable structure, good drying effect, low regeneration gas consumption, long working life, good use effect of composite desiccant, and its service life is more than three times longer than ordinary adsorbent.

⊙ regeneration adsorption dehydration technology, high-precision coalescence oil removal dehydration filter element, 0.01 μ m precision filter to ensure air cleanliness, easy operation, energy saving, safe and reliable.

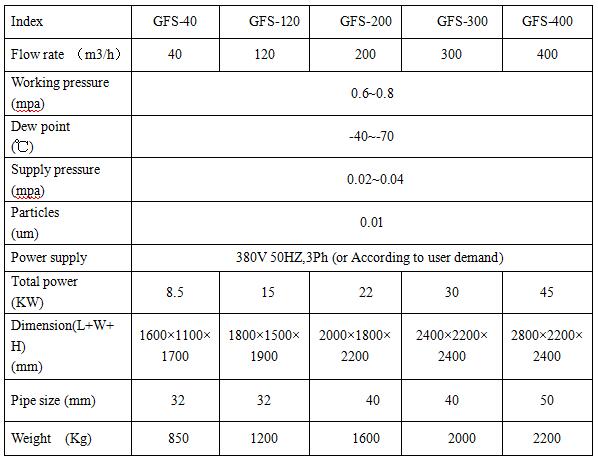

Technical parameters table:

Equipment quality requirements, technical standards: strictly in accordance with the national quality standards, technical standards, inspection standards, after passing the factory, the goods provided are brand new and unused. The whole machine is guaranteed for 3 years. During the warranty period, three guarantees will be implemented for major equipment problems. Any abnormal problems will be handled by the supplier free of charge. If it occurs outside the warranty period, the supplier will provide lifelong free technical services and only charge the cost of accessories.

Material selection of the whole equipment: the main body of the whole machine is high carbon steel, and the consumables are stainless steel sheet mesh filter materials (which can be cleaned and reused for many times). The main body can choose stainless steel material for oil pipeline according to the user's requirements. Domestic or imported brands can be selected for oil pump and electrical related main components, or explosion-proof is required. Imported filter element or designated brand can be used for filter element.

Chongqing Zhongjing Filter Equipment Manufacturing Co., Ltd. packing: conventional fumigation packaging for wooden box export, and the equipment meets the requirements of long-distance transportation at home and abroad.

Equipment transportation mode: automobile, aircraft, ship logistics transportation, the company will replace and repair the goods free of charge until customer satisfaction.

Chongqing Zhongjing filtration equipment manufacturing Co., Ltd

Manager Zhang 0086-18580036904 (wechat same number) 0086-02386194345

Supply cycle: the standard type is available in stock.

Contact: Mr.Zhang

Phone: 0086-18580036904

Tel: web:http://www.zjzklyj.com/

Add: No. 137 Cave Industrial Park, Shapingba District, Chongqing