Product ID:China

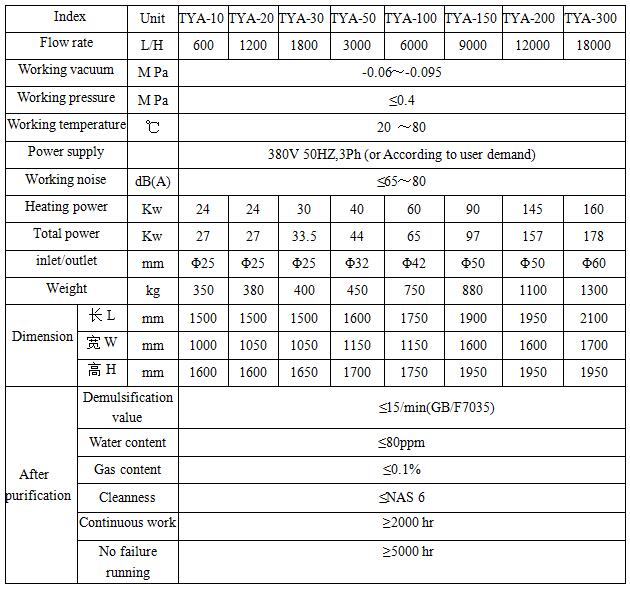

Product Info1:TYA-10/TYA-30/TYA-50/TYA-100/TYA-150

Product Info2:TYA series vacuum oil purifier for lubricating oil

Shelf time:2020-11-18

Product description:The equipment is used for small lubricating oil filter 1800L/H lubricating oil vacuum filter 3000L/H and vacuum oil purif

Product Usage:

TYA series special vacuum oil filter for lubricating oil is used in machinery, metallurgy, mining, petroleum, chemical and other fields, for hydraulic oil, machine oil, cooling oil, refrigerating oil, gear oil, gasoline engine oil, diesel engine oil, heat treatment oil and other lubricating oils Purification of the product. It can quickly remove harmful components such as moisture, impurities and volatiles (such as ammonia) in the oil, improve the quality of the oil, and restore its performance. Ensure the normal operation of hydraulic system, power system and lubrication system.

Features:

1. The machine is advanced in process design, and can be matched with the hydraulic oil tank and the process connection of the oil station. Online processing can also be processed offline, with high automation, compact size, flexible and convenient movement.

2. Oil-water separation system; vacuum separation adopts German vacuum separation technology and three-dimensional spiral atomization flash rapid evaporation technology, which can quickly separate water and gas in the oil.

3. Filtration system: advanced magnetic filter; used for oil absorption filtration, filtering out solid particles and fine ferrous substances in the oil medium, and effectively controlling the pollution degree of ferrous impurities in the working medium. The use of high-quality filter elements and connection sealing materials with high temperature resistance, good mechanical strength, meets the requirement of high heating temperature for filtering high viscosity oil, and expands the range of purified oil.

4. Heating system; safe and reliable circulating carbon fiber heating technology is adopted to ensure uniform heating and stable oil temperature while reducing energy consumption.

5. Condensing device: It adopts advanced strong air cooling technology and medium condensing device, which can quickly cool the water vapor separated from the oil and prolong the service life of the equipment.

6. Control system; optimized design of control interlocking protection device, overpressure alarm shutdown protection, phase sequence protection, etc. ensure long-term reliable operation of the whole machine. A number of advanced technologies such as automatic pressure alarm shutdown system, automatic overload protection system, automatic constant temperature system, automatic fuel injection protection, etc. ensure the fully automated and safe operation of the equipment.

7. The influence of lubricant contamination;

1. Air will accelerate the oxidation of the oil, make the oil foam during the heating and cooling process, reduce the rigidity of the oil system, the action response is slow, and the lubrication system components will be damaged due to air pockets.

2. Moisture is a common pollutant in oil. It makes oil turbid, accelerates oxidation, generates water-soluble acid, precipitates additives, decreases viscosity, and reduces lubricating performance.

3. There are 3 ways of water that is common in oil; A. Suspended. Water is suspended in the oil in the form of droplets. B. Emulsified. Refers to the tiny water droplets evenly dispersed in the oil. C. Dissolved state. Moisture exists in the form of being dissolved in oil. 3. Solid particles --- will seriously damage the system components, if allowed to circulate in the oil, it will cause a chain reaction of wear.

Product parameters:

Equipment quality requirements, technical standards: strictly in accordance with the national quality standards, technical standards, inspection standards, after passing the factory, the goods provided are brand new and unused. The whole machine is guaranteed for 3 years. During the warranty period, three guarantees will be implemented for major equipment problems. Any abnormal problems will be handled by the supplier free of charge. If it occurs outside the warranty period, the supplier will provide lifelong free technical services and only charge the cost of accessories.

Material selection of the whole equipment: the main body of the whole machine is high carbon steel, and the consumables are stainless steel sheet mesh filter materials (which can be cleaned and reused for many times). The main body can choose stainless steel material for oil pipeline according to the user's requirements. Domestic or imported brands can be selected for oil pump and electrical related main components, or explosion-proof is required. Imported filter element or designated brand can be used for filter element.

Chongqing Zhongjing Filter Equipment Manufacturing Co., Ltd. packing: conventional fumigation packaging for wooden box export, and the equipment meets the requirements of long-distance transportation at home and abroad.

Equipment transportation mode: automobile, aircraft, ship logistics transportation, the company will replace and repair the goods free of charge until customer satisfaction.

Chongqing Zhongjing filtration equipment manufacturing Co., Ltd

Manager Zhang 0086-18580036904 (wechat same number) 0086-02386194345

Supply cycle: the standard type is available in stock.

Contact: Mr.Zhang

Phone: 0086-18580036904

Tel: web:http://www.zjzklyj.com/

Add: No. 137 Cave Industrial Park, Shapingba District, Chongqing