Product ID:China

Product Info1:TY-10/TY-20/TY-30/TY-50/TY-100/TY-150

Product Info2:TY coalescence and separation turbine oil purifier

Shelf time:2020-11-18

Product description:The equipment is suitable for TY-20 vacuum oil purifier 1200L/H, TY-30 steam turbine oil purifier 2000L/H, TY-50 turbine

Product introduction:

TY coalescing and separating turbine oil purifier processes unqualified industrial lubricants such as turbine oil, turbine oil, machine oil, hydraulic oil, compressor oil, and refrigerating oil. The multifunctional coalescing and separating oil purifier can quickly and effectively remove the moisture, gas, magazines and volatiles (such as alcohol, gasoline, ammonia, etc.) in the oil, and restore the oil's viscosity, flash point and performance. The treated turbine oil has low emulsification value, very little water content, and high impurity accuracy. It can be reused in high-precision equipment at home and abroad. It is suitable for the purification and regeneration of various oil products in petroleum, chemical, mining, metallurgy, electric power, transportation, machinery manufacturing, railway and other industries.

Features:

1. The coalescence and separation vacuum oil purifier uses advanced coalescence and separation materials as the medium, integrating demulsification and vacuum precision filtration. Combined with a special oil-water separation device, it can effectively separate the water in the oil, and the dehydration efficiency is extremely high. It can perform on-line demulsification, dehydration, and impurity removal treatments for the turbine oil in operation, as well as dehydration and impurity removal treatments for light oil with high water content.

2. The coalescing separation vacuum oil filter is used in the filtration and dehydration system of steam turbine oil. It integrates two functions of precise filtration and high-efficiency dehydration of oil, which can effectively remove particulate impurities, emulsified water and free water in the oil. Improve oil quality, reduce reprocessing and pollution costs, and reduce maintenance and use costs. An explosion-proof controller can be used for the electrical control part. The oil flow part can be made of stainless steel.

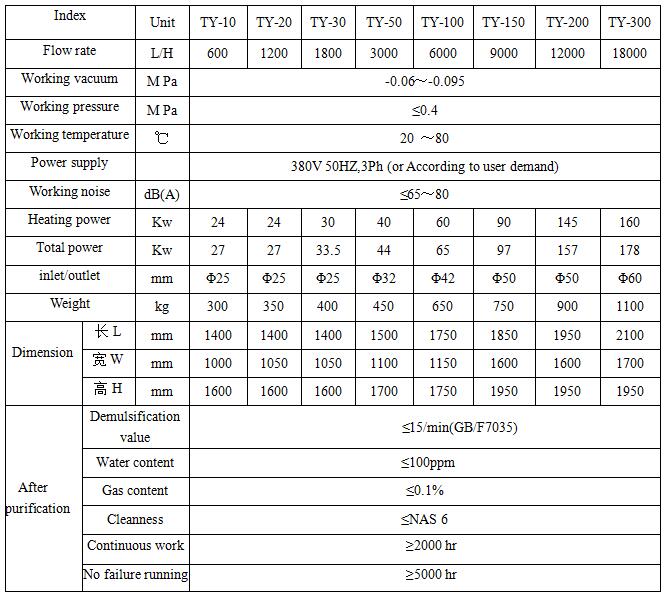

Technical Parameters:

Equipment quality requirements, technical standards: strictly in accordance with the national quality standards, technical standards, inspection standards, after passing the factory, the goods provided are brand new and unused. The whole machine is guaranteed for 3 years. During the warranty period, three guarantees will be implemented for major equipment problems. Any abnormal problems will be handled by the supplier free of charge. If it occurs outside the warranty period, the supplier will provide lifelong free technical services and only charge the cost of accessories.

Material selection of the whole equipment: the main body of the whole machine is high carbon steel, and the consumables are stainless steel sheet mesh filter materials (which can be cleaned and reused for many times). The main body can choose stainless steel material for oil pipeline according to the user's requirements. Domestic or imported brands can be selected for oil pump and electrical related main components, or explosion-proof is required. Imported filter element or designated brand can be used for filter element.

Chongqing Zhongjing Filter Equipment Manufacturing Co., Ltd. packing: conventional fumigation packaging for wooden box export, and the equipment meets the requirements of long-distance transportation at home and abroad.

Equipment transportation mode: automobile, aircraft, ship logistics transportation, the company will replace and repair the goods free of charge until customer satisfaction.

Chongqing Zhongjing filtration equipment manufacturing Co., Ltd

Manager Zhang 0086-18580036904 (wechat same number) 0086-02386194345

Supply cycle: the standard type is available in stock.

Contact: Mr.Zhang

Phone: 0086-18580036904

Tel: web:http://www.zjzklyj.com/

Add: No. 137 Cave Industrial Park, Shapingba District, Chongqing