Product ID:China

Product Info1:ZhongJing

Product Info2:Trailer type double stage transformer oil purifier

Shelf time:2020-11-20

Product description:Product Usage: The trailer-type two-stage transformer oil purifier can quickly and deeply remove the harmful components i

Product Usage:

The trailer-type two-stage transformer oil purifier can quickly and deeply remove the harmful components in the oil such as moisture, gas and impurities in the insulating oil, and improve the insulation performance of the oil. The filtered oil can effectively ensure the safe and normal operation of power equipment. The equipment is used in power plants, power stations, power companies, substation industries, metallurgy, petrochemical, machinery, transportation, railways and other industries. Especially for the on-site inspection and repair of transformers in large-scale substations above 110KV and the deep purification of high-grade new oil, imported oil, transformer oil, ultra-high voltage transformer oil and other oil products. It can also be used for vacuum oiling and drying of transformers. Can live on-site work. The trailer-type two-stage oil filter comes with its own trailer, which can be used for remote construction operations. It is equipped with a pressurized Roots pump, which has higher vacuum and more stable.

Features:

1. Trailer type, fully enclosed structure, waterproof and dustproof, easy to move.

2. Install car tires, bridge shock absorbers, brake assembly, and welded steel structure of the whole car to ensure a driving speed of 60KM/H.

3. Two-stage vacuum pumping speed and advanced dehydration and degassing system, using large-area three-dimensional flash evaporation technology, can quickly and efficiently remove water, impurities, hydrocarbons and other harmful components in the oil, and improve the flash point of insulating oil And compressive strength.

4. It can meet the requirements of vacuuming and vacuum filling the transformer body at the installation or maintenance site.

5. Precise filtration system, high-quality filter element, multi-stage filtration and step-by-step encryption can effectively remove mechanical impurities in the oil, and it is equipped with automatic detection function of filter element pollution.

6. Automatic constant temperature control system, automatic liquid level control system, automatic defoaming control system, automatic pressure protection system and sophisticated configuration ensure high-performance operation of the equipment.

7. Online oil filtering, unmanned operation, the running status is displayed by the indicator light.

8. This machine has humanized design, low noise, easy operation, long maintenance interval, low energy consumption and saving operating cost.

9. The whole machine is equipped with interlocking safety protection, the oil discharge system, the vacuum system and the heating system are interlocked to avoid adverse effects caused by misoperation.

10. With filter element replacement instructions, filter element saturation shutdown device.

11. Equipped with leakage and overload shutdown device to protect the motor.

12. Equipped with phase sequence and phase loss protection functions, and safety control for sudden shutdown.

13. Equipped with external vacuum system for transformer.

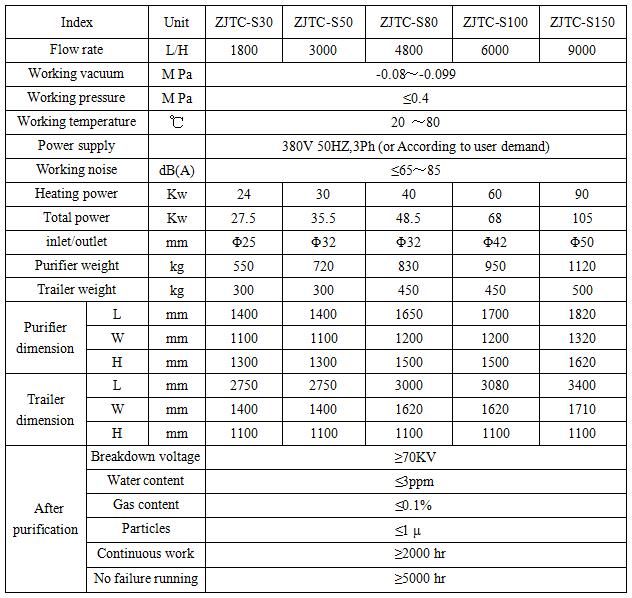

Product parameters:

Product optional configuration:

1. Optional imported online moisture detector and breakdown voltage tester.

2. Optional fuel gun, ordinary flow meter and digital display flow meter.

3. The color of the body can be optional blue, green, white, etc.

4. Imported foam sensor can detect foam in the oil in time, prevent oil running, and operate safely online.

5. Optional insulation oil regeneration device is used together to achieve the functions of acid removal, decolorization, free carbon removal, and dielectric loss reduction.

Equipment quality requirements, technical standards: strictly in accordance with the national quality standards, technical standards, inspection standards, after passing the factory, the goods provided are brand new and unused. The whole machine is guaranteed for 3 years. During the warranty period, three guarantees will be implemented for major equipment problems. Any abnormal problems will be handled by the supplier free of charge. If it occurs outside the warranty period, the supplier will provide lifelong free technical services and only charge the cost of accessories.

Material selection of the whole equipment: the main body of the whole machine is high carbon steel, and the consumables are stainless steel sheet mesh filter materials (which can be cleaned and reused for many times). The main body can choose stainless steel material for oil pipeline according to the user's requirements. Domestic or imported brands can be selected for oil pump and electrical related main components, or explosion-proof is required. Imported filter element or designated brand can be used for filter element.

Chongqing Zhongjing Filter Equipment Manufacturing Co., Ltd. packing: conventional fumigation packaging for wooden box export, and the equipment meets the requirements of long-distance transportation at home and abroad.

Equipment transportation mode: automobile, aircraft, ship logistics transportation, the company will replace and repair the goods free of charge until customer satisfaction.

Chongqing Zhongjing filtration equipment manufacturing Co., Ltd

Manager Zhang 0086-18580036904 (wechat same number) 0086-02386194345

Supply cycle: the standard type is available in stock.

Contact: Mr.Zhang

Phone: 0086-18580036904

Tel: web:http://www.zjzklyj.com/

Add: No. 137 Cave Industrial Park, Shapingba District, Chongqing