Product ID:China

Product Info1:ZhongJing

Product Info2:Single-stage horizontal vacuum oil purifier

Shelf time:2020-11-20

Product description:Product Usage: Single-stage horizontal vacuum oil purifier series are mainly suitable for the purification of insulating

Product Usage:

Single-stage horizontal vacuum oil purifier series are mainly suitable for the purification of insulating oil such as high-voltage transformers, current transformers, capacitors, circuit breakers, and oil switches. The equipment has offline and online functions, which can clean the degraded transformers, transformers, oil switches and other insulating oils without power failure. It can also be distributed and concentrated. The single-stage oil filter can separately dry, vacuum, and vacuum oil the insulating equipment with water, gas, impurities, etc. After the oil filter is processed, the insulating oil can quickly reach the insulation index and restore the stability of the oil.

Features:

1. Single-stage oil filter developed by our company. On the basis of the original vacuum oil filter, it has made greater improvements. It adopts a multi-stage negative pressure filter horizontal structure, with stable and advanced vacuum performance, reliable electrical design and installation, compact appearance and reasonable structure.

2. The purification cycle is short, the energy consumption is low, no filter paper and vulnerable materials are used, and the degree of automation is high. Automatic control protection device, light and flexible, low power consumption, low noise and convenient operation.

3. The polymer composite filter material directly removes the free carbon in the power insulating oil. It can effectively ensure the filtering accuracy of the oil, that is, the cleanliness, and the filter equipment has an automatic backwash.

4. Unique and efficient dehydration and degassing system. Using large-area three-dimensional flash evaporation technology, it can quickly separate water and gas in oil.

5. Precise filtration system, high-quality filter element, multi-stage filtration step-by-step encryption, which can effectively remove mechanical impurities in the oil, and is equipped with automatic detection function of filter element pollution.

6. The heating system adopts the most optimized pipeline design to ensure uniform heating and stable oil temperature.

7. Automatic constant temperature control system, automatic liquid level control system, automatic defoaming control system, automatic pressure protection system and sophisticated configuration ensure high-performance operation of the equipment.

8. Online oil filtering, unmanned operation, the operation status is displayed by the indicator light.

9. The whole machine is equipped with interlocking safety protection, and the oil discharge system, vacuum system and heating system are interlocked to avoid adverse effects caused by misoperation.

10. With filter element replacement instructions, filter element saturation shutdown device.

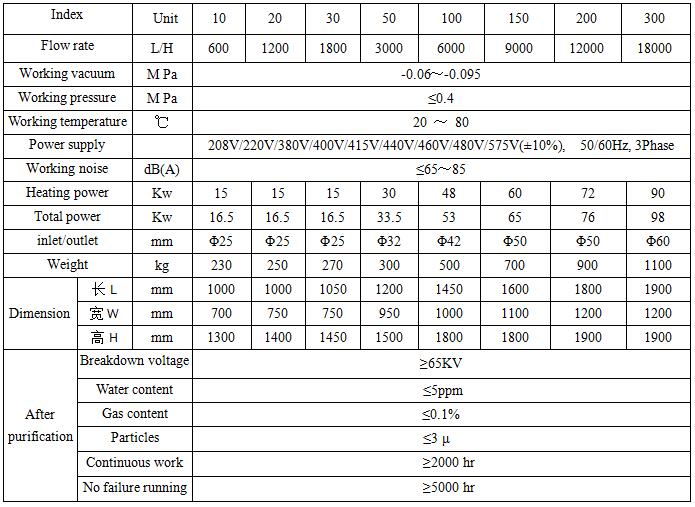

Product parameters:

Equipment quality requirements, technical standards: strictly in accordance with the national quality standards, technical standards, inspection standards, after passing the factory, the goods provided are brand new and unused. The whole machine is guaranteed for 3 years. During the warranty period, three guarantees will be implemented for major equipment problems. Any abnormal problems will be handled by the supplier free of charge. If it occurs outside the warranty period, the supplier will provide lifelong free technical services and only charge the cost of accessories.

Material selection of the whole equipment: the main body of the whole machine is high carbon steel, and the consumables are stainless steel sheet mesh filter materials (which can be cleaned and reused for many times). The main body can choose stainless steel material for oil pipeline according to the user's requirements. Domestic or imported brands can be selected for oil pump and electrical related main components, or explosion-proof is required. Imported filter element or designated brand can be used for filter element.

Chongqing Zhongjing Filter Equipment Manufacturing Co., Ltd. packing: conventional fumigation packaging for wooden box export, and the equipment meets the requirements of long-distance transportation at home and abroad.

Equipment transportation mode: automobile, aircraft, ship logistics transportation, the company will replace and repair the goods free of charge until customer satisfaction.

Chongqing Zhongjing filtration equipment manufacturing Co., Ltd

Manager Zhang 0086-18580036904 (wechat same number) 0086-02386194345

Supply cycle: the standard type is available in stock.

Contact: Mr.Zhang

Phone: 0086-18580036904

Tel: web:http://www.zjzklyj.com/

Add: No. 137 Cave Industrial Park, Shapingba District, Chongqing