Product ID:China

Product Info1:LY-30/LY-50/LY-100/LY-150/LY-200

Product Info2:LY plate and fr<x>ame turbine oil purifier

Shelf time:2020-11-18

Product description:The equipment is suitable for LY plate and fr ame oil filter 30L/MIN BASY plate and fr ame pressurized oil filter 50L/MIN

Product Usage:

Plate and frame pressure oil filter (pressurized filter) has small oil filter 30L/MIN, plate and frame oil filter 50L/MIN, explosion-proof plate and frame oil filter 100L/MIN, plate and frame plus Oil filter models such as pressure oil filter 150L/MIN, plate and frame pressure oil filter 200L/MIN. The equipment is used to filter water and impurities in transformer oil, insulating oil, turbine oil, hydraulic oil, fuel oil, coal mill oil, heat treatment oil, etc. It is widely used in power plants, power stations, industrial and mining, cement plants, lubricating oil depots, Shipbuilding, petroleum, chemical, metallurgy, defense industry and other industry units. This equipment is also often used in power plants and power stations as auxiliary filtering equipment for steam turbine oil vacuum oil purifiers or insulating oil vacuum oil purifiers to improve oil cleanliness and filtration efficiency. The plate and frame pressure oil filter (pressurized filter) is composed of filter bed, oil pump and coarse filter. With industrial filter paper as the filter medium, different filter papers can be selected according to different filtration requirements, with high filtration accuracy. It has the advantages of simple structure, easy operation and low operating cost.

Features:

1. The advantages of simple structure, simple operation, low operating cost, and no restriction on the site.

2. High filtration accuracy, large filtration area, and wide range of applicable oil products. According to the characteristics of oil products, different quality filter materials can be selected to meet the requirements of suitable filtration accuracy.

3. Traditional filtration equipment, effective and economical filtration equipment.

4. Using filter paper as the filter material, with high filtration accuracy, it can absorb a small amount of water in the oil, and it is convenient and quick to replace the filter paper.

5. Simple structure, convenient movement, easy operation and low operating cost.

6. It can work continuously, has high processing efficiency and fast speed, and is suitable for oil products with more impurities.

7. It has a wide range of uses, and can carry out high-precision filtration treatment for most oils with low viscosity.

8. The independent plate and frame filter system effectively increases the filter area and is suitable for oils with high impurities.

Product operation and use:

Before use, check the installation position of the filter plate and filter frame of the filter part. Starting from the thrust plate, the first piece is the plate, the second piece is the frame, the third piece is the plate, the fourth piece is the frame... Arrange by analogy, the number of plates is one more than the frame, and the plates and frames cannot be reversed. If they are installed reversely, they will not be able to filter. The grease coated on the plates, frames, thrust plates and compression plates must be removed. Before the test run, filter paper should be clamped between the plates and frames to press the plates and frames tightly.

Before starting the machine, the oil pump shaft must be rotated by hand for two or three revolutions. It is considered that the rotation is flexible and there is no card group phenomenon. Then connect the oil-resistant hose (or iron pipe) to the oil suction and discharge ends of the oil filter, and then check the inlet Whether the oil pipe is blocked or leaking oil or gas, open the oil inlet and outlet valves, close the oil return valve and the pressure reducing valve (connected to the oil inlet and outlet ends of the oil pump), and then start the machine.

The correct rotation direction of the motor is the direction indicated by the arrow on the oil pump cover and gear pump nameplate, and it cannot be reversed.

If everything is normal, the oil pump will suck oil within a few seconds after starting up. If it still does not suck oil for half a minute, it means that the suction end of the oil pump and the oil sample valve are leaking. You should stop working immediately and try again after troubleshooting to prevent gears. The pump is damaged when there is no oil.

If the value indicated by the pressure gauge is found to be as high as 0.4-0.6Mpa after starting the machine, and the oil pump makes an abnormal noise, stop immediately to find out the fault and eliminate it.

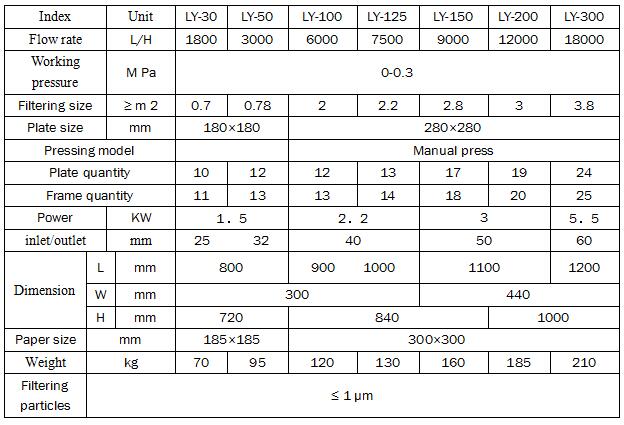

Technical Parameters:

Equipment quality requirements, technical standards: strictly in accordance with the national quality standards, technical standards, inspection standards, after passing the factory, the goods provided are brand new and unused. The whole machine is guaranteed for 3 years. During the warranty period, three guarantees will be implemented for major equipment problems. Any abnormal problems will be handled by the supplier free of charge. If it occurs outside the warranty period, the supplier will provide lifelong free technical services and only charge the cost of accessories.

Material selection of the whole equipment: the main body of the whole machine is high carbon steel, and the consumables are stainless steel sheet mesh filter materials (which can be cleaned and reused for many times). The main body can choose stainless steel material for oil pipeline according to the user's requirements. Domestic or imported brands can be selected for oil pump and electrical related main components, or explosion-proof is required. Imported filter element or designated brand can be used for filter element.

Chongqing Zhongjing Filter Equipment Manufacturing Co., Ltd. packing: conventional fumigation packaging for wooden box export, and the equipment meets the requirements of long-distance transportation at home and abroad.

Equipment transportation mode: automobile, aircraft, ship logistics transportation, the company will replace and repair the goods free of charge until customer satisfaction.

Chongqing Zhongjing filtration equipment manufacturing Co., Ltd

Manager Zhang 0086-18580036904 (wechat same number) 0086-02386194345

Supply cycle: the standard type is available in stock.

Contact: Mr.Zhang

Phone: 0086-18580036904

Tel: web:http://www.zjzklyj.com/

Add: No. 137 Cave Industrial Park, Shapingba District, Chongqing