Product ID:China

Product Info1:ZhongJing

Product Info2:Explosion proof turbine oil purifier

Shelf time:2020-11-18

Product description:Explosion-proof turbine oil purifier is suitable for turbine oil explosion-proof oil purifier TY-30L/MIN, lubrication sys

product description:

Explosion-proof turbine oil purifiers are mainly used in places where flammable and explosive gases and dust are contained in electric power, coal, petroleum and chemical industries, and where explosions may occur. Such as flammable gas, dust environment, oil refinery, petrochemical plant, coal mine, etc. The equipment adopts integral explosion-proof configuration, explosion-proof motor, explosion-proof electric control box, explosion-proof solenoid valve, explosion-proof fan, etc. Explosion-proof turbine oil filter is especially suitable for treating severely emulsified turbine oil and water turbine turbine oil. This machine has a strong vacuum degassing ability, oil-water separation ability, particle purification ability, removal of free carbon and impurities, etc., so that the quality indicators of the oil meet the new oil standard and ensure the safe operation of the steam turbine unit.

Features of explosion-proof turbine oil vacuum oil filter:

1. Quickly remove the free water in the oil, and the free water content of the medium after treatment is less than 100PPm.

2. The filter element has high precision, large dirt holding capacity, long service life of the filter element, and automatic detection of the pollution degree of the filter element.

3. Online oil filtering, unmanned operation, the running status is displayed by the indicator light.

4. This machine has humanized design, low noise, easy operation, long maintenance interval, low energy consumption, and save operation cost.

5. Equipped with filter element replacement instructions and a shutdown device for filter element saturation.

6. Equipped with leakage and overload shutdown device to protect the motor.

The explosion-proof turbine oil filter unit adopts a progressive encryption filter setting. The primary filter is made of stainless steel and can be repeatedly cleaned and used. The fine filter is an imported filter material.

A. Heating system:

The heating system is composed of heaters, temperature controllers and other parts; multiple heaters can be used alone or at the same time; the start of the heater is controlled by the temperature difference set by the temperature controller; the temperature controller must be at the same time as the vacuum pump and the oil pump It can be started only when it is running. This three-way interlocking not only ensures the safe operation of the heater, but also prevents the generation of "dead" oil areas and the aging of oil. It can also monitor the temperature of the heating system and control the heater Work within a set temperature range; if the output temperature of the equipment is higher than 60℃, the heater stops working, when the temperature is lower than 60℃, the heater is put into operation; when the heater temperature exceeds the protection set point Automatically cut off the operation of the heater to ensure the safety of equipment, oil and personnel.

C. Vacuum system:

The vacuum system is composed of vacuum separator, vacuum pump, condenser, cooler and other parts. Using the principle of "cavitation", the contact area of the oil in the vacuum separator is expanded hundreds of times, and the "cavitation" system increases the oil evaporation surface area, and the evaporation interface is constantly updated to maximize The oil travel in the vacuum system and the static water volatilization area.

D. Automatic control and protection system:

The automatic control system is composed of infrared sensors, motors, solenoid valves, and protection components.

1) When the oil temperature reaches the set point, the temperature controller sends a signal that the heater stops working, otherwise the heating is put into operation.

2) The start and stop of the heater are controlled by the interlock of the temperature controller, oil pump and vacuum pump (see "Heating System" above); when the heater temperature exceeds the set value (the factory setting is 60°C), the heater stops working.

3) The oil intake is automatically controlled by the oil intake valve, solenoid valve, infrared liquid level sensor and oil pump.

4) When the oil is higher than the upper infrared control oil level, the oil inlet solenoid valve is automatically closed; when the oil is lower than the upper infrared control oil level, the oil inlet solenoid valve is automatically opened.

Routine maintenance should be carried out according to the following requirements during operation:

1. Check for oil leakage and deal with it immediately.

2. Check the spray effect through the observation window on the vacuum separator.

3. Check the operation of the instrument.

4. Make sure to clean the oil filter at the end of every day.

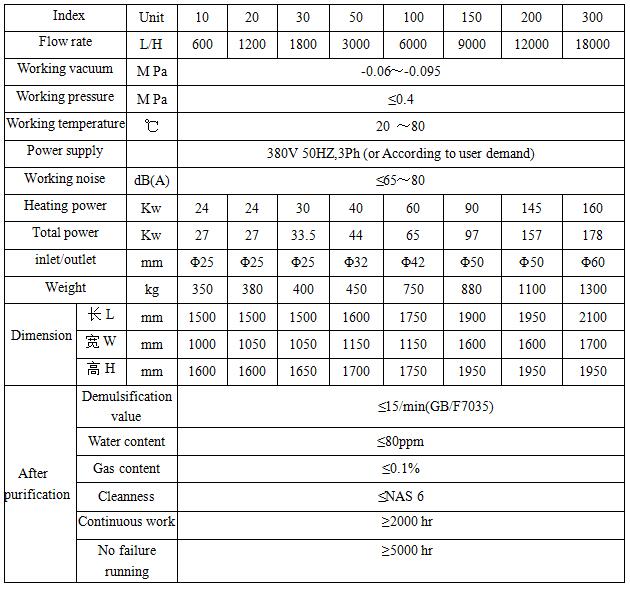

Technical Parameters:

Equipment quality requirements, technical standards: strictly in accordance with the national quality standards, technical standards, inspection standards, after passing the factory, the goods provided are brand new and unused. The whole machine is guaranteed for 3 years. During the warranty period, three guarantees will be implemented for major equipment problems. Any abnormal problems will be handled by the supplier free of charge. If it occurs outside the warranty period, the supplier will provide lifelong free technical services and only charge the cost of accessories.

Material selection of the whole equipment: the main body of the whole machine is high carbon steel, and the consumables are stainless steel sheet mesh filter materials (which can be cleaned and reused for many times). The main body can choose stainless steel material for oil pipeline according to the user's requirements. Domestic or imported brands can be selected for oil pump and electrical related main components, or explosion-proof is required. Imported filter element or designated brand can be used for filter element.

Chongqing Zhongjing Filter Equipment Manufacturing Co., Ltd. packing: conventional fumigation packaging for wooden box export, and the equipment meets the requirements of long-distance transportation at home and abroad.

Equipment transportation mode: automobile, aircraft, ship logistics transportation, the company will replace and repair the goods free of charge until customer satisfaction.

Chongqing Zhongjing filtration equipment manufacturing Co., Ltd

Manager Zhang 0086-18580036904 (wechat same number) 0086-02386194345

Supply cycle: the standard type is available in stock.

Contact: Mr.Zhang

Phone: 0086-18580036904

Tel: web:http://www.zjzklyj.com/

Add: No. 137 Cave Industrial Park, Shapingba District, Chongqing